Anti-foaming agent, also known as anti-foaming agent, will produce many harmful foams in the process of industrial production, and it is necessary to add anti-foaming agent. It is widely used to remove harmful foam produced in the production process of latex, textile sizing, food fermentation, biomedicine, coating, petrochemical, papermaking, industrial cleaning, sewage treatment and other industries. Defoaming and anti-foaming in various sewage treatment and various industrial water systems.

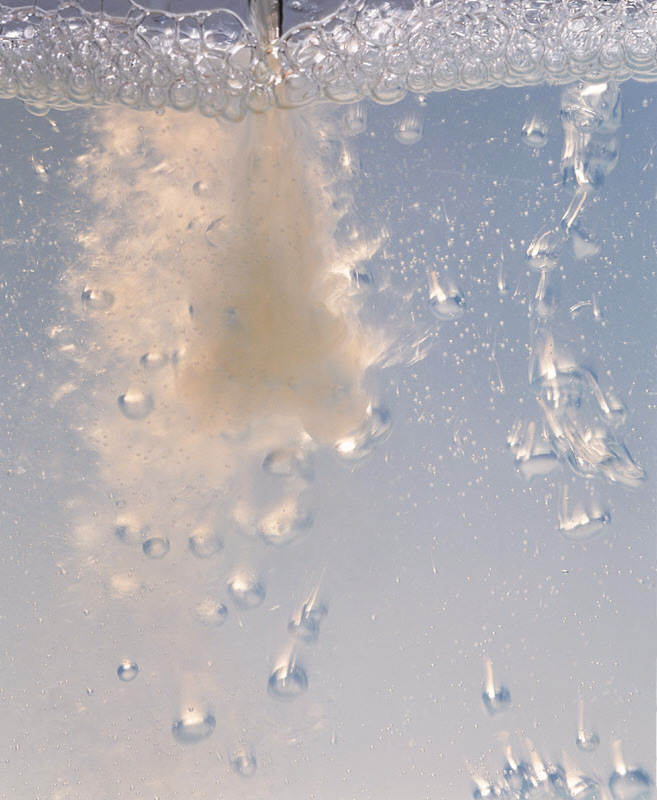

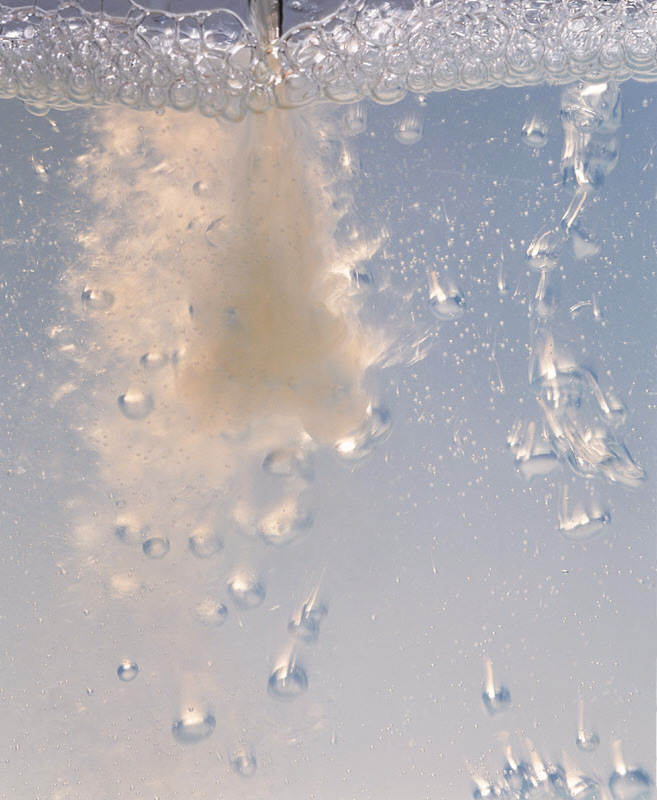

The origin of the defoaming mechanism of defoamers is to sprinkle higher alcohol or vegetable oil on the foam. When it dissolves into the foam liquid, it will significantly reduce the surface tension there. Because these substances are generally less soluble in water, the reduction in surface tension is limited to the local area of the foam, and the surface tension around the foam hardly changes. The part with reduced surface tension is pulled and extended to the surroundings, and finally ruptures.

When the

defoamer is added to the foam system, it will diffuse to the gas-liquid interface, making it difficult for the foam-stabilizing surfactant to recover the elasticity of the film. The rate of foam drainage can reflect the stability of the foam. Adding a substance that accelerates the foam drainage can also play a defoaming effect. The hydrophobic solid particles on the surface of the bubbles will attract the hydrophobic end of the surfactant, making the hydrophobic particles hydrophilic and enter the water phase, thereby playing a defoaming effect.

Some low-molecular substances that can be fully mixed with the solution can solubilize the bubble surfactant and reduce its effective concentration. Low-molecular substances with this effect, such as octanol, ethanol, propanol and other alcohols, can not only reduce the surfactant concentration of the surface layer, but also dissolve into the surfactant adsorption layer to reduce the tightness between surfactant molecules. Degree, thereby weakening the stability of the foam.

For the interaction of the electric double layer of the surfactant with the foam to produce a stable foaming liquid, the addition of ordinary electrolyte can disintegrate the electric double layer of the surfactant to have a defoaming effect.

1. Alkali-resistant defoamer

Under the condition of high temperature and strong alkali, it can defoam quickly and inhibit foam for a long time. Good stability, low dosage, high efficiency, no oil bleaching; widely used in papermaking cooking black liquor treatment, strong alkali type refining agent in textile printing and dyeing industry, strong alkali condition cleaning agent and other high temperature and strong alkali aqueous systems Defoaming.

2. Acid-resistant defoamer

Composed of fatty acid esters and fatty amides, it is widely used in wet-process phosphoric acid, titanium dioxide production, boric acid production and other strong acid systems.

3. High-viscosity foam defoamer. This product is a high-efficiency composite defoamer developed for the foam produced by paper pulping black liquor, chemical beneficiation, and special chemical reactions. It has the characteristics of high viscosity, fine foam, and difficulty in elimination. Foaming agent.

4. Coating defoamer contains a variety of high-quality defoaming ingredients, so it has a wide range of applications. It is especially suitable for eliminating foam in systems such as styrene-acrylic latex, ethylene-propylene latex, pure acrylic latex, and vinyl acetate latex.

5. Papermaking defoamer can effectively control pulp and foam overflow and improve papermaking quality. It is widely used for defoaming in papermaking systems, and can also be used for defoaming in papermaking wastewater treatment, antifreeze, and distillation systems.

6. Cement mortar defoamer can effectively control the foam production in the cement mortar system, making the concrete components more compact and bright.

7. Oilfield industrial defoamer can effectively control the internal foam production in the oilfield industrial process and improve the oil production efficiency.

8. The defoamer for cleaning can effectively control the foam produced by the cleaning agent.

9. Cationic system defoamer can effectively control the production of foam containing cationic system. It is widely used in cationic rosin glue and cationic cleaning agent for papermaking, and it can also be used in papermaking sewage treatment, antifreeze, and distillation system defoaming.

10. High-efficiency fermentation defoaming agent overcomes the shortcomings of ordinary silicone defoaming agents of poor high temperature resistance and short foam suppression time; the foam that rises and accumulates in the fermentation tank can be quickly eliminated like polyether, and the product has polyether Ether can not match the advantages of time foam suppression.

Top Win is one of the leading & professional manufacturers with more than 20 years' experience, have domestic top-level engineers in silicone surfactant industry. We specialized in producing all kinds of SILICONE BASED new materials and specialized in research, production, sales and marketing in silicone-based performance materials.Provide good OEM&ODM service.Our products are mainly used in polyurethane foam, textile and leather, inks and coatings, paper release coating, personal care and agriculture, etc.