Industry News

Jul 05, 2025

Hangzhou Topwin Technology: Exploring the Innovation Path of Silicone Oil Market Application

Jun 19, 2025

Welcome to visit Topwin at the Shanghai International Tape & Film Expo 2025.

Exhibition Dates: June 17th to 19th , 2025

Exhibition Venue: Shanghai National Exhibition and Convention Center

Booth Number: 6.1 T22

Jun 13, 2025

The cratering and shagreen (orange peel) defects in the coating when using a silicone-based emulsion/ Slip agent could be related to several factors

Jun 12, 2025

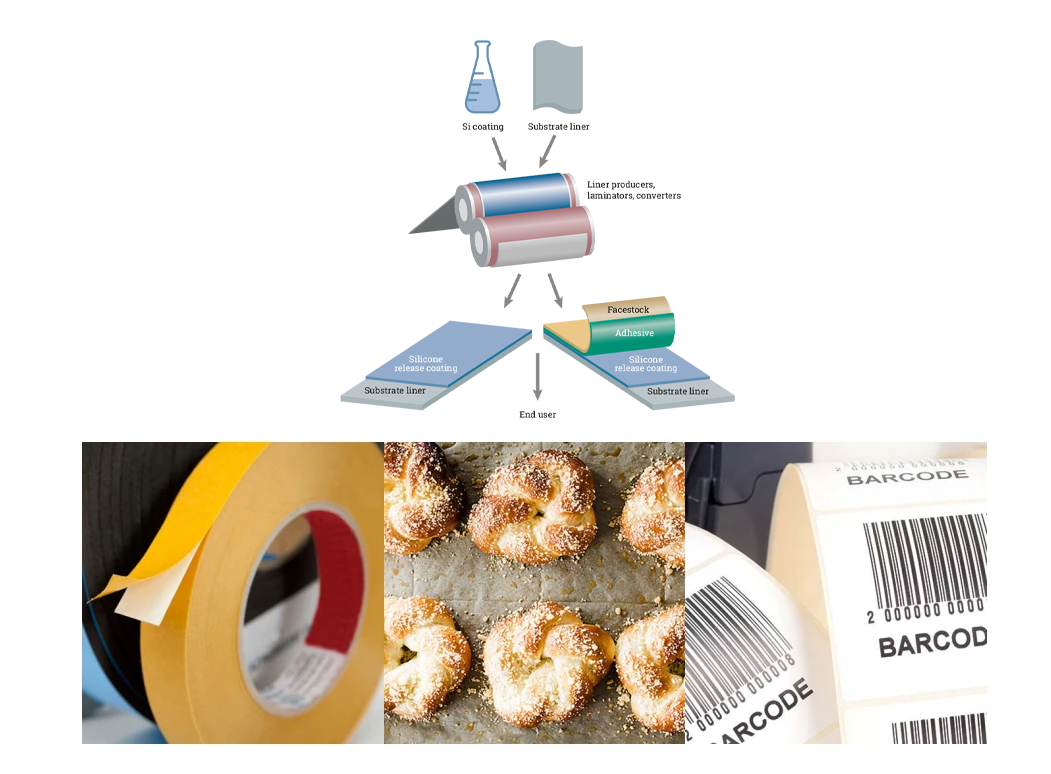

Silicone release coatings are designed to facilitate the easy detachment of adhesive surfaces from their backing materials. These coatings ensure a controlled release, making them essential across various industries, from packaging to medical applications.

Jun 12, 2025

The viscosity of silicone release coating significantly affects the coating machine's line speed, a relationship widely recognized and emphasized in actual production processes. Specifically, the viscosity of silicone release coating is closely related to the coating machine's line speed, primarily reflected in the following aspects:

May 29, 2025

Release films (also known as peeling films or release liners) are functional films coated with a special release agent to form a low-surface-energy layer. This layer effectively isolates adhesive materials (e.g., adhesives, resins) to prevent sticking during processing, transportation, or storage, while ensuring easy peeling in subsequent operations.

May 29, 2025

Silicone release coatings are widely used on glassine paper, primarily as backing paper for products such as self-adhesive labels, adhesive tapes, and medical patches. Their primary function is to provide controlled release forces, ensuring seamless peeling of adhesive materials without residue.

May 29, 2025

Application of Silicone Release Coating in Baking Paper:

Synergistic Advancements in Technology and Food Safety

May 08, 2025

Welcome to visit Topwin at Labelexpo Southeast Asia 2025

Exhibition Dates: May 08th to 10th , 2025

Exhibition Venue: BITEC, 88 Bangna-Trad Road (Km.1), Bang Na, Bangkok 10260, Thailand

Booth Number: H11

Apr 28, 2025

In 2024, the global MDI capacity was 10.99 million tons per year. From 2020 - 2024, the compound annual growth rate (CAGR) of global MDI capacity was 5.3%. It is expected that by 2029, the global MDI capacity will reach 12.5 million tons per year, and from 2025 - 2029, the CAGR of global MDI capacity will be 3.1%.

May 29, 2025

To Mitigate Tariff Impacts, enterprises should try their best to find specific strategies, such as reduce costs to maintain orders, optimize supply chains……to mitigate tariff impart.

May 29, 2025

Silicone spray adjuvants have become an essential tool in modern agriculture, enhancing the performance of pesticides, herbicides, and fungicides. These adjuvants are derived from organic silicone compounds, primarily polydimethylsiloxanes (PDMS), which improve the spreading, wetting, and penetration of agrochemicals on plant surfaces.

May 29, 2025

A critical component behind the efficiency of self-adhesive labels is the release coating—a thin layer that allows the label to peel off smoothly without leaving residue or damaging the adhesive.

May 29, 2025

A non-hydrolyzable silicone surfactant designed for flexible polyurethane foam production plays a crucial role in stabilizing the foam structure during the foaming process. Here's a breakdown of what it is and why it's important:

May 29, 2025

Welcome to visit Topwin at LABELEXPO MEXICO 2025

Exhibition Dates: April 1st to 3rd, 2025

Exhibition Venue: Av. Mariano Otero #1499, Col. Verde Valle, Guadalajara, Jalisco, México.

Booth Number: C88

May 29, 2025

Solventless-type silicones are considered an excellent choice for environmental protection due to several key characteristics that make them both eco-friendly and high-performance. Here's why they are a great option:

May 29, 2025

Sincerely welcome to visit Topwin PU Tech Expo 2025 for polyurethane communication

Exhibition Time: March 12 - 14, 2025

Exhibition Hall: Bangkok, Thailand

Venue: Hall 101, BITEC - Bangna

Booth No.: T9

May 29, 2025

Silicones, semiorganic polymers composed of silicon atoms interspersed with oxygen atoms and methyl groups attached to the silicon atoms, exhibit a basic polymer structure known as polydimethylsiloxane.