Designed for direct food contact and regulatory compliance, widely used in baking paper, confectionery packaging, and frozen food liners to ensure clean release and hygiene.

4. Applications of Silicone Release Coatings

Silicone release coatings are widely used across industries for their durable non-stick performance, process efficiency, and product quality benefits. Key application areas include:

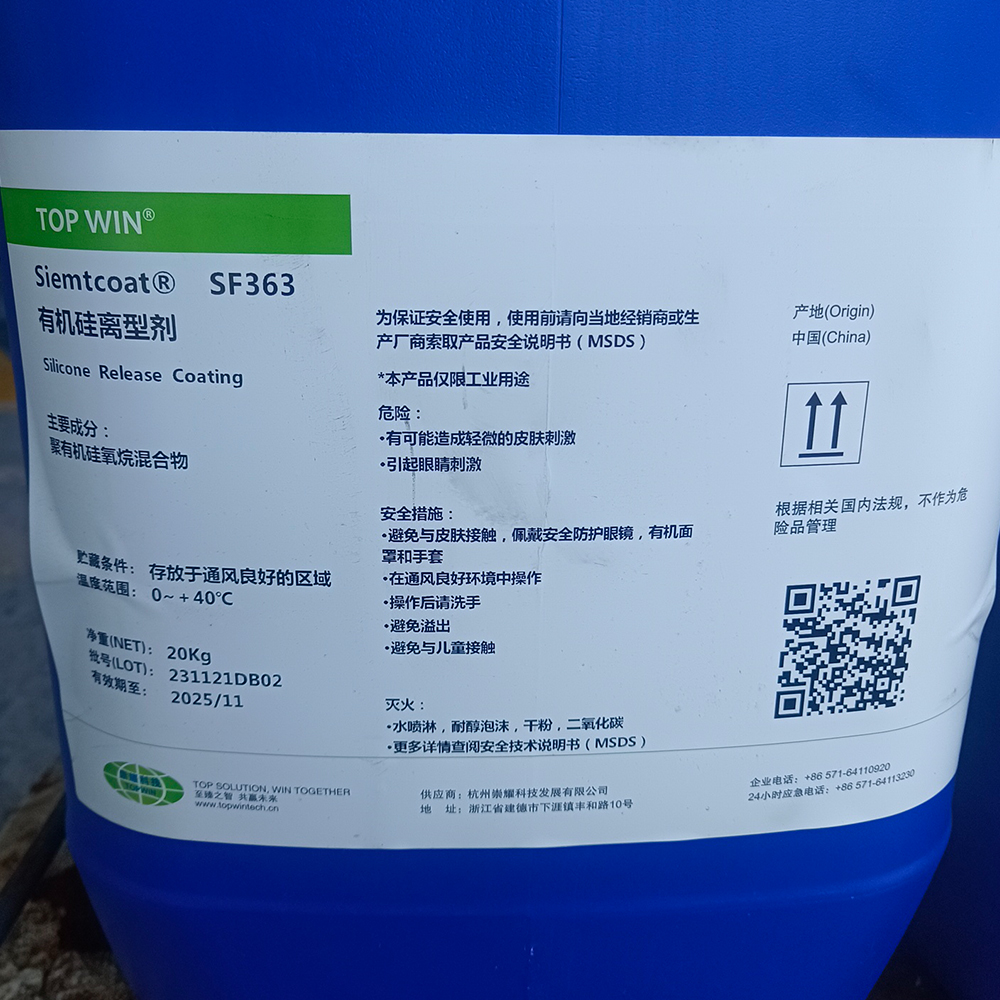

Food Packaging & Processing

Used on baking paper, cardboard, and liners to prevent sticking of baked goods, confectionery, and frozen foods while maintaining hygiene and food safety.

Medical & Pharmaceutical

Essential for bandage packaging, wound dressings, transdermal patches, medical tapes, and blister packs, ensuring clean release and sterility.

Labels & Pressure-Sensitive Adhesives

A core component of release liners for labels, tapes, and stickers, enabling smooth peeling without residue.

Automotive & Industrial Manufacturing

Applied in molding, die casting, composites, and electronics assembly to prevent adhesion, reduce defects, and improve production efficiency.

Used in nonwoven fabrics, diapers, feminine hygiene products, and cosmetic patches to enhance processing, comfort, and functionality.

5. Selecting the Right Silicone Release Coating

Choosing the right silicone release coating starts with understanding your application. Consider the substrate, operating temperature, required release force, and exposure to chemicals, moisture, or UV. For example, food packaging demands FDA-compliant coatings, while electronics favor heat resistance and stability.

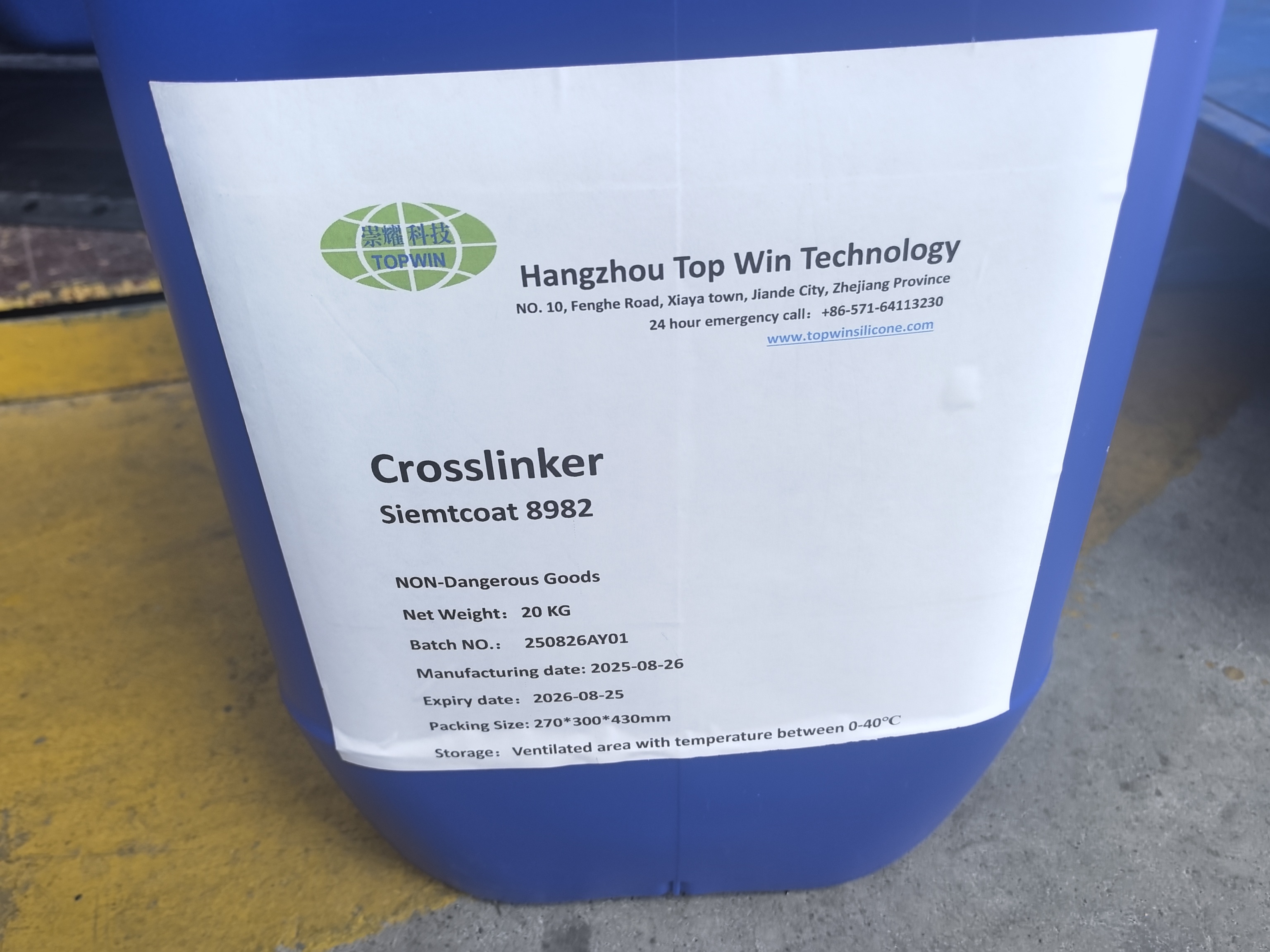

Common Release Systems

Solvent-based: Fast curing, excellent uniformity

Solventless: VOC-free, environmentally friendly

Water-based emulsions: Cost-effective, ideal for paper and fabric

UV-curable: Instant curing, high efficiency

Key Selection Criteria

Focus on release force, durability, cure speed, transfer resistance, and long-term stability. Substrate compatibility is critical—mismatches can cause adhesion failure or coating breakdown.

Think Long Term

Evaluate total cost, not just material price. Factors like curing energy, production speed, waste reduction, and compliance often make higher-performance coatings the more economical choice over time.