How to improve the subsequent adhesion rate(二)?

Release force climb is mainly caused by undesired physical and chemical changes between the silicone oil coating and the adhesive under high-temperature conditions (such as mutual penetration, blocked migration of silicone oil, post-curing, and changes in physical properties).

-

Increasing crosslink density: Resisting high-temperature climb requires building a denser and more stable crosslinked network.

-

Enhancing coating cohesion: To resist high-temperature softening.

-

Reducing the mobility of silicone oil molecular segments at high temperatures, inhibiting their excessive migration into the adhesive or deep mutual penetration with the adhesive.

-

Selecting high-efficiency crosslinking agents and catalysts: Choose crosslinking agents with high reactivity that can form stable crosslinking bonds (e.g., Si-C bonds are more hydrolysis-resistant than Si-O-Si bonds), such as hydrogen-containing silicone oil. Use high-efficiency platinum catalysts to ensure complete and sufficient reactions. Consider using delayed catalysts to achieve a better process window.

-

Adequate curing: Ensure the coating is fully and uniformly cured on the coating line to avoid local under-curing, which may become a weak point during high-temperature aging.

-

Appropriately increasing coating thickness: This can provide more "silicone oil reserves." At high temperatures, even if the surface silicone oil undergoes slight changes (structuring, contamination by substances in the adhesive), the lower layer can still provide release functionality, helping to buffer the magnitude of release force climb. However, this needs to be balanced against costs, coating processability, and the requirement to reduce residual adhesive.

-

Controlling winding tension: Avoid excessive tightness, which may cause the inner layer of the film roll to be in a high-pressure state for a long time, potentially inducing physical changes in the coating or migration of additives.

-

Choosing base films with high Tg and thermal stability: Select PET base films with high crystallinity, low thermal shrinkage, and high glass transition temperature.

-

Controlling thermal shrinkage of base films: During high-temperature aging, excessive shrinkage of the base film will cause stress on the coating, possibly leading to coating cracking, wrinkling, or abnormal release force. Choosing base films with low thermal shrinkage is crucial.

-

Cleanliness and thermal stability of base films: Ensure that the base film does not precipitate low-molecular-weight substances (such as oligomers, slip agents, antistatic agents) at high temperatures. These substances migrating to the coating surface will contaminate the interface, resulting in release force climb.

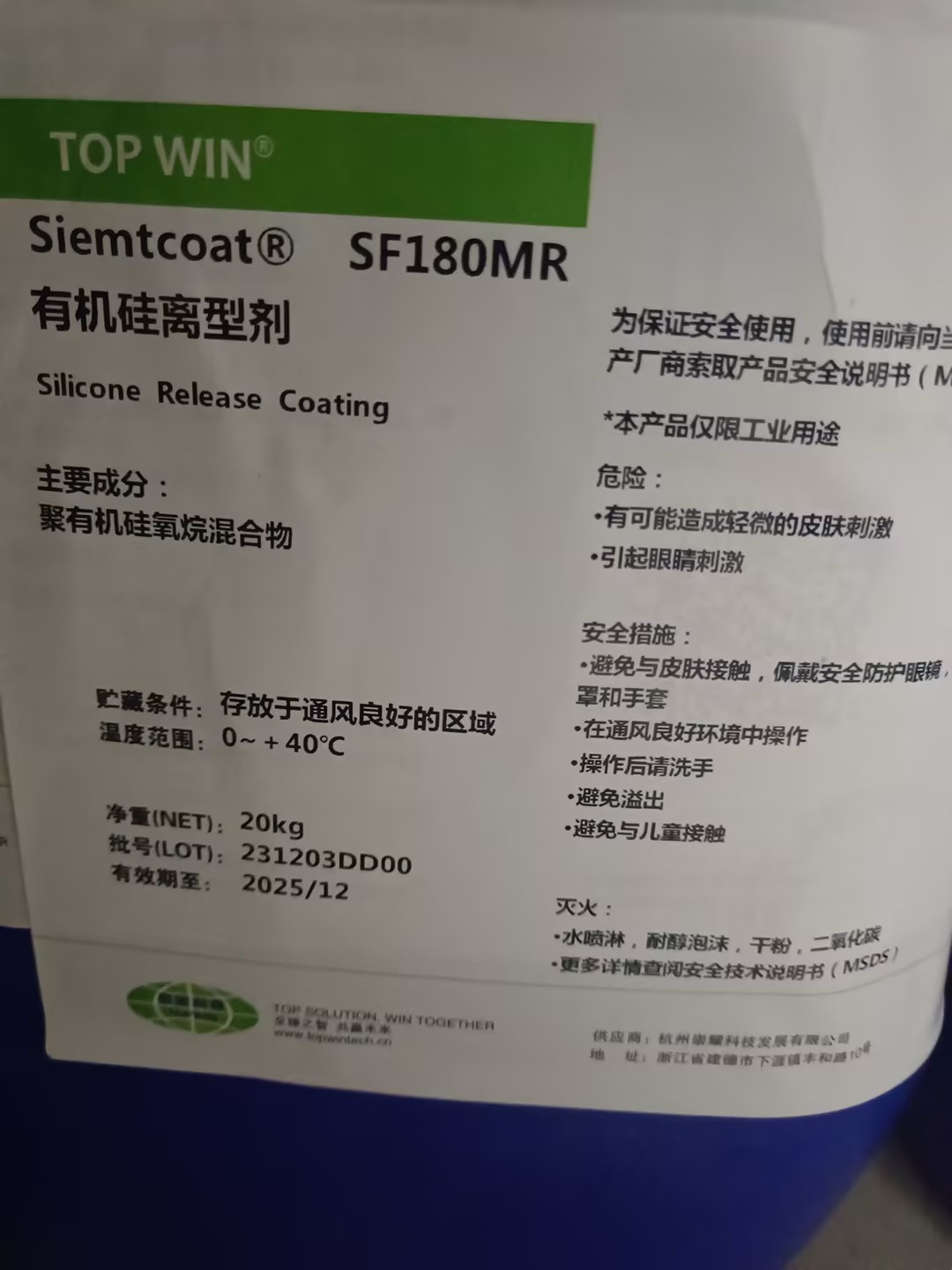

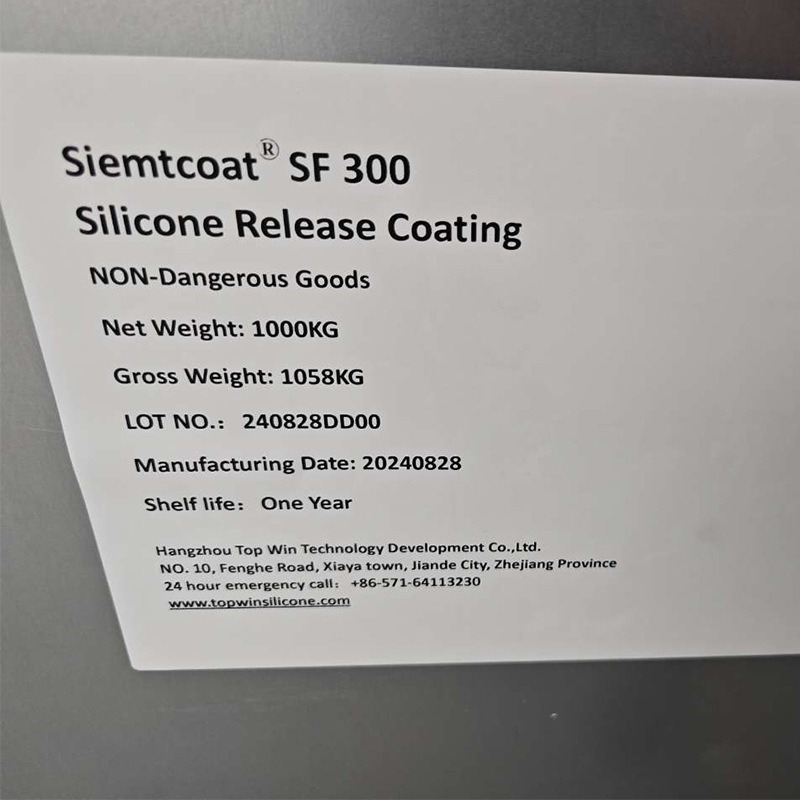

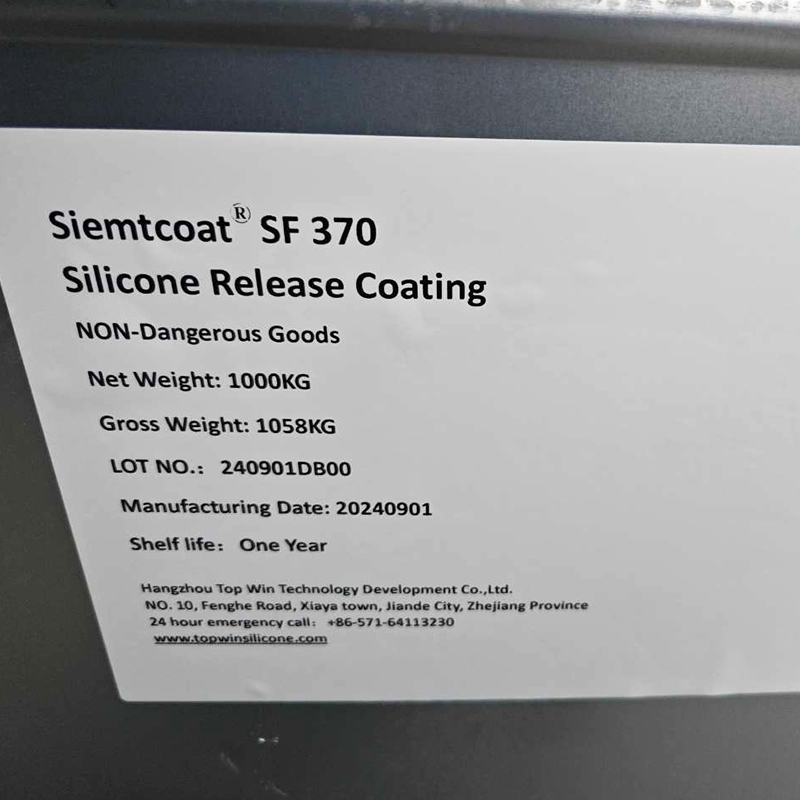

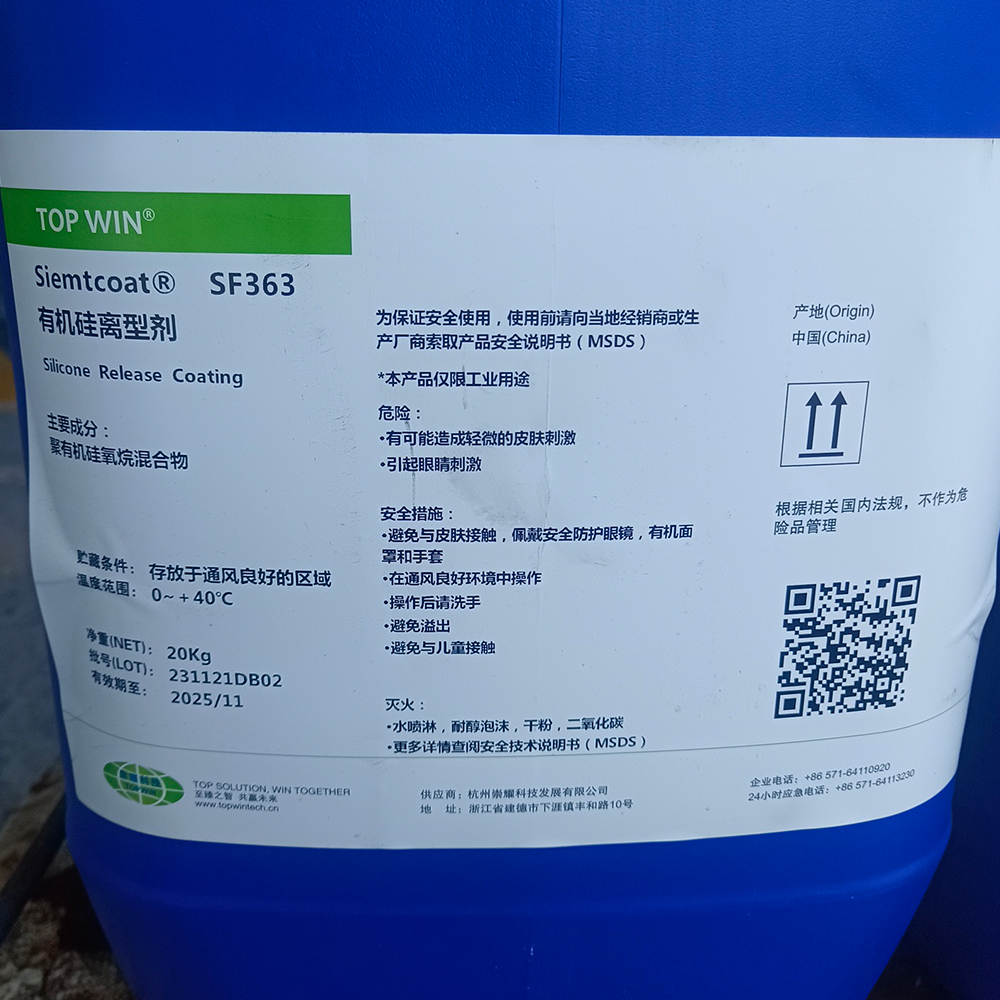

Topwin is one of the leading professional manufacturers and solution providers with more than 20 years of experience, and has domestic top-level engineers in the silicone surfactant industry. Specializing in research and development, production, sales, and marketing of silicone-based special functional performance materials, Topwin also serves as a professional provider of technical services. Our products are mainly used in Polyurethane Foam, Corp Protection, Coatings and Inks, Leather & Textile, Silicone Release Coating for Paper and Film, Personal Care, and others.