Stable release force, Good anchorage performance, Suitable for double-sided PE coated paper

| Appearance | Clear liquid |

| Active(%) | 100 |

| Vis(mm 2 /s,25℃) | 350 |

| Density (g/cm³) | 0.97 |

- When applicate SF300H into Siemtcoat system, please following bellowing ratio and mixing process:

. 1- Weight the main polymer SF300H-------------- XXp

. 2- Weight the crosslinker

- Siemtcoat® 8982--------------------- XXp

. 3- Mix the crosslinker and make sure it was dispenser well.

. 4- Weight the catalyst Siemtcoat® 5000 and add in during mixing Siemtcoat® 5000------------------------ XXp

(Attention: do not mix the crosslinker and catalyst directly as dramatic reaction would happen.)

. 5- Mix until the catalyst even.

- The detail information could consult us for the formulation advice

Bath life

- All Siemtcoat system bath life is relative to the formulation, equipment, mixing

- Process, temperature and environment. SF300H additive would not change the

- Siemtcoat original bath life (Normally about 5 hours at 40℃)

Release force

- Release force performance is relative for many factors.

- We measure the release force with different substrate and adhesive to define the

- Release force performance. While the standard release force measure could use

- Standard tape to measure.

- Typical release force performance:

- Tesa Tape 7475 (23℃) — 5 to 15 g/25mm (0.3m/min peeling speed)

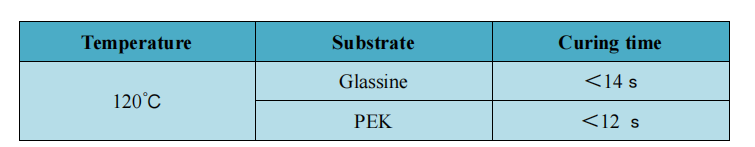

Curing

- Siemtcoat system curing results is relative the formulation, quality for substrate,

- Curing temperature and oven efficiency. We acquired the following results :

(Curing time define as the minimum curing time without smear, no rub-off and migration of release coating layer)

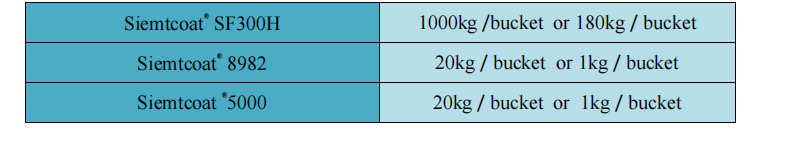

Package

Shelf-life

- Siemtcoat SF300H should be storage in a closed container at -20°C to +30°C temperature.

- Siemtcoat standard shelf-life is 24 months。The expired day is marked on label for each drum.

Safety

- Please referents Siemtcoat® SF300H,8982,5000 MSDS.