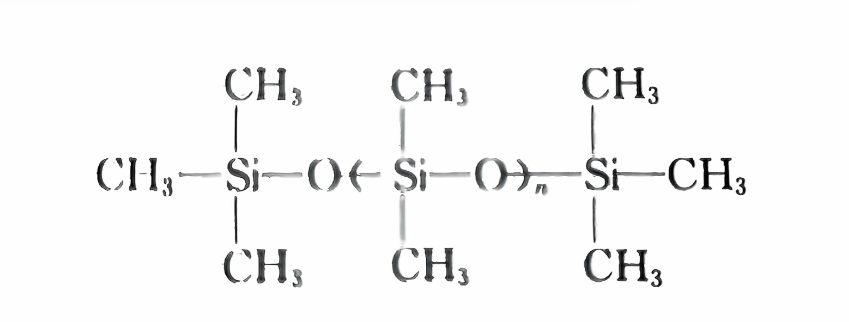

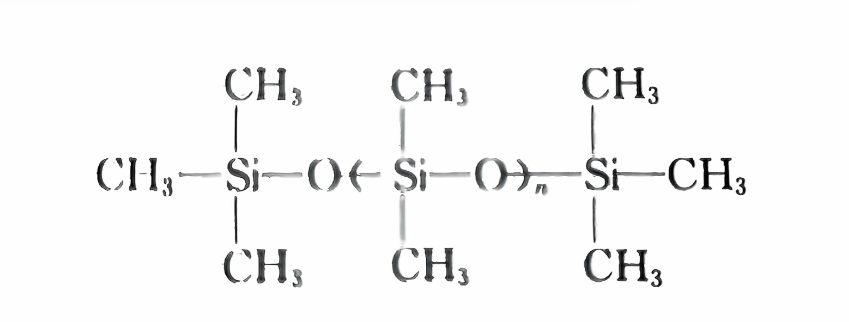

Silicone oil is a liquid linear polysiloxanes with a molecular structure primarily composed of repeating siloxane bonds (Si-O) as the backbone, where silicon atoms are connected to organic groups.It is the most abundant and widely used type of silicone (silicone) material. Polydimethylsiloxane (dimethyl silicone oil) is the most important linear polyorganosiloxane, and its molecular structure can be represented by the following formula:

n in the formula represents the degree of polymerization, ranging from 0 (with a viscosity of 0.65 mm²·s⁻¹ at 25°C) up to 4,000 (with a viscosity of 1,000,000 mm²·s⁻¹ at 25°C) ,even 7,000 (with a viscosity of 20,000,000 mm²·s⁻¹ at 25°C). Its molecular chain is highly flexible, and the bond energy, bond angle, and bond length of the siloxane bond are all relatively large, giving it many unique properties. The most outstanding characteristics of dimethyl silicone oil are its excellent temperature resistance, weather resistance, low surface tension, and physiological inertness, making it one of the most extensively studied and widely used silicone oil.

By replacing some of the methyl groups in linear polydimethylsiloxane molecules with other organic groups, new properties and applications can be achieved, such as high- and low-temperature resistance, radiation resistance,enhances oil and solvent resistance, imparts softness and smoothness to textiles. We are specialized for polyether modified silicone.Replacing with polyether groups (polyether-modified silicone) improves surface activity and provides hydrophilicity and antistatic properties.

Silicone oil was the first silicone material to be recognized and industrially produced. To meet the needs of new and specialized applications, novel structural varieties continue to be developed, and existing varieties are finding broader application areas. Silicone oil remains an open and promising field for technological development.

While some silicone oils can be directly applied as commercial products, most are used in combination with other materials, processed under specific conditions to form composite products, emulsions, solutions, and other application forms, also known as secondary processed silicone oil products. These mainly include silicone greases, silicone pastes, compound oil agents, defoamers, release agents, anti-adhesive agents, and fiber treatment agents. The development of secondary processed silicone oil products and their application technologies has unlocked the potential of silicone oils in many fields, enabling their practical use across various industries and contributing to the advancement of many sectors.

Topwin is one of the leading professional manufacturers and solution providers with more than 20 years of experience, and has domestic top-level engineers in the silicone industry. Specializing in research and development, production, sales, and marketing of silicone-based special functional performance materials, Topwin also serves as a professional provider of technical services. Our products are mainly used in Polyurethane Foam, Corp Protection, Coatings and Inks, Leather & Textile, Silicone Release Coating for Paper and Film, Personal Care, and others.