Polydimethylsiloxane is a hydrophobic

silicone material. It is used in medicine, daily chemical products, food, construction and other fields, and its derivatives have reached hundreds. The commonly used polysiloxanes mainly include polydimethylsiloxane, cyclomethylsiloxane, amino siloxane, Polymethylphenyl siloxane, polyether polysiloxane copolymer and so on. Cyclopolydimethylsiloxane is one of the commonly used polysiloxanes.

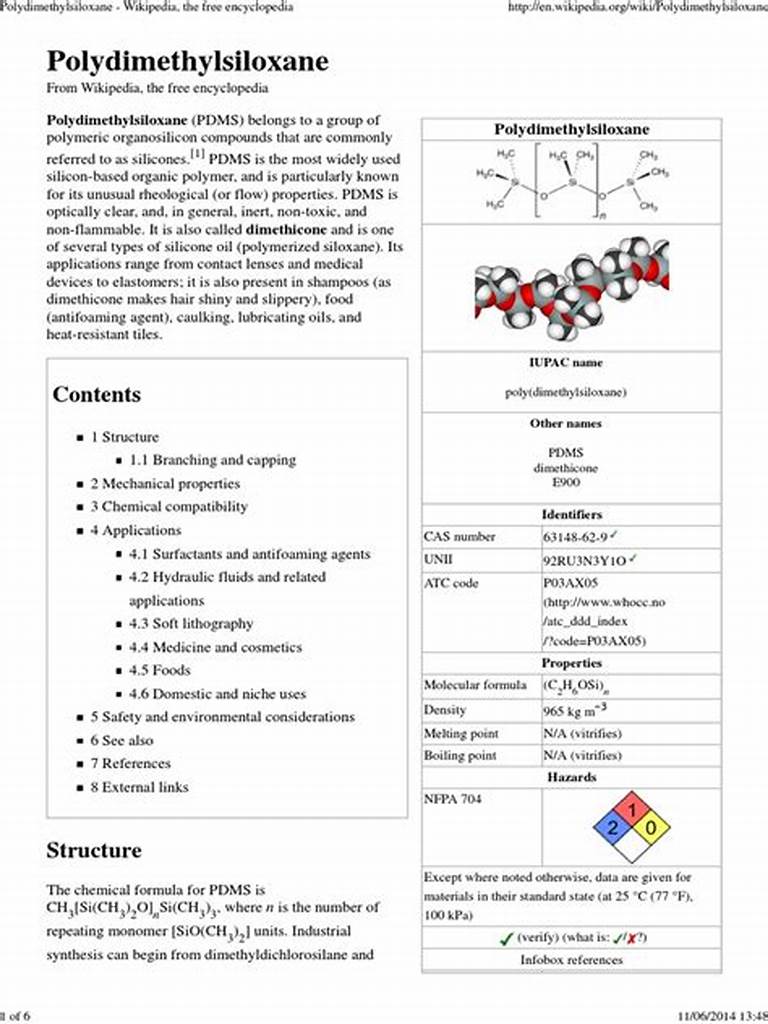

Physical and chemical properties

The chemical state of polydimethylsiloxane is dimethyl silicone oil. According to the relative molecular weight, the appearance changes from colorless and transparent volatile liquid to extremely high viscosity liquid or silica gel. It is tasteless and transparent. It has heat resistance, cold resistance, small viscosity change with temperature, water resistance, small surface tension and thermal conductivity. The thermal conductivity is 0.134-0.159w / (m · K), The light transmittance is 100%. Dimethyl silicone oil is non-toxic and tasteless. It has physiological inertia and good chemical stability. It has good electrical insulation, weather resistance and hydrophobicity, and has high shear resistance. It can be used for a long time at - 50 ℃ ~ 200 ℃. With excellent physical properties, it can be directly used in moisture-proof insulation, damping, shock absorption, defoaming, lubrication, polishing and other aspects. It is widely used as insulation lubrication, shock prevention, oil dust prevention, dielectric fluid and heat carrier. And used as defoaming, release agent, paint and daily chemical additives.

Polydimethylsiloxane can be mixed with Lanolin, stearyl alcohol, cetyl alcohol, glyceryl monostearate, tween, span and other

surfactants as emulsion matrix. Adding film forming agents such as PVP, PVA and cellulose derivatives to this product can enhance its protection. The drug release and penetration into the skin were faster than those of dolphin fat, lanolin and vaseline.

application area

Cosmetics

The combination of low application, surface tension, easy spreading and appropriate viscosity gives

personal care products a feeling of lubrication and greasiness, and makes the skin soft. It has the functions of foam inhibition, defoaming and antifoaming, and prevents the "whitening" phenomenon when applying products. Different products need to choose different viscosity. The higher the viscosity, the more oily, and the lower the viscosity gives the skin a dry and cool feeling. Due to its deposition, the dosage in the cosmetic formula is low. The characteristics of the product can be adjusted by using polydimethylsiloxane with different viscosity grades. [1]

Electrical products

Polydimethylsiloxane can be used for electronic connectors in electrical and electronic industry.

Leather products

Polydimethylsiloxane can be used for fiber and

leather: hydrophobic agent, softener, hand feel improver, defoamer in dyeing industry and lubrication of sewing thread. The emulsion can be applied to leather fatliquoring, thereby enhancing the hydrophobicity, softness and comfort of leather. Using it to treat leather surface can enhance wear resistance, water resistance and demoulding.

Brightener

Poly two methyl siloxane is suitable for automotive, furniture, footwear, cement products and other brightener ingredients, including automotive brighteners, foam furniture cleaners, vinyl roof cleaners, and brightening formula for building materials. The best results can be achieved at the least amount.

Release agent

Polydimethylsiloxane can be used as

release agent for rubber or plastic products (brake plate, screw head, plug, etc.) and EVA shoe materials. It can be used directly or diluted 10-200 times with low hardness water. The product is efficient, stable and widely used.

lubricant

Polydimethylsiloxane can be used as lubricant for extruded rubber products such as conveyor belts. It can be used as a lubricant in the following textile processes: yarn weaving, suture lubrication, socks and underwear production, suture needle lubrication, glass fiber filter screen.

Other areas

Polydimethylsiloxane is a food grade defoamer, which can be used for defoaming of medicine, food brewing and fermentation time. Because it is non-toxic and will not cause physiological reactions in human body, it is also used as a medical defoamer for the treatment of acute pulmonary edema and flatulence. Substances called silicones (or silicone oil) in pharmaceutical monographs are the general name of a class of silicone oxidized polymers. Dimethyl silicone oil is only one of its commonly used drugs. In addition, there are ethyl silicone oil, methyl phenyl silicone oil, wax containing silicone oil and so on. In the tablet polishing agent insect wax, a small amount of this product is often added to enhance the one-sided brightness and moisture resistance. As a kind of ointment, it is easy to be coated on clothes and has good hydrophobicity, so it is not an ideal lubricant for normal skin. It is often combined with oily matrix to make protective ointment, which is used to prevent the stimulation or corrosion of water-soluble substances, acids and lyes.

Top Win is one of the leading & professional manufacturers with more than 20 years' experience, have domestic top-level engineers in

silicone surfactant industry. We specialized in producing all kinds of SILICONE BASED new materials and specialized in research, production, sales and marketing in silicone-based performance materials. Provide good OEM&ODM service.Our products are mainly used in

polyurethane foam,

Agriculture,Coatings and Inks, Leather & Textiles, Pulp and Paper, Cosmetic industry, etc.