Water-based

defoamers are water-based after emulsification with emulsifiers and other fillers. Oil-based defoamers are not emulsified. They are composed of mineral oil or polyether and are used as paper-making defoamers.

In the pulp and paper industry, foam handling is a thorny issue in production. From the operation of the pulping unit after the ball is discharged to the coating process, there are different degrees of foam, which seriously affects the normal production and paper quality. However, traditional mineral oil, sulfonated vegetable oil, alcohol and other defoaming The surface activity of the agent is poor, the defoaming efficiency is low, and the application range is narrow, which cannot meet user requirements. At present, the paper industry at home and abroad mainly uses three types of broad-spectrum defoamers, which are fatty acid amides, polyethers, and silicones, which have strong versatility, high efficiency, good compatibility, and great market potential. As a new type of auxiliary agent, silicone defoamer has attracted widespread attention in the paper industry.

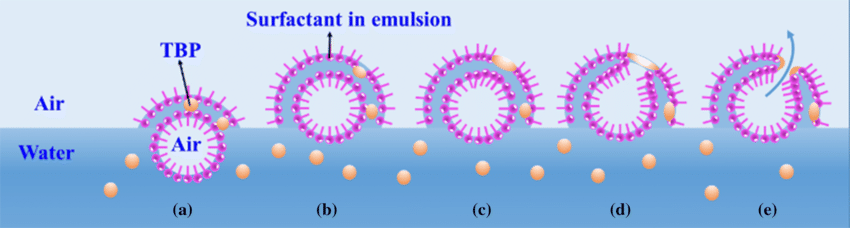

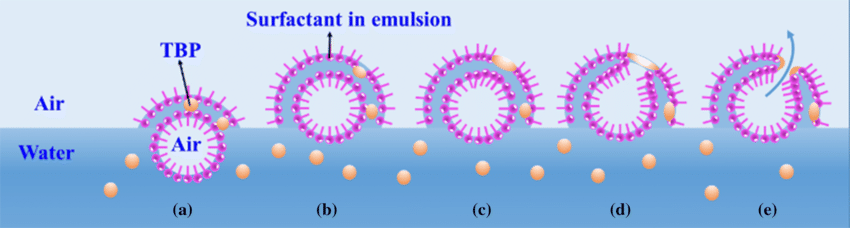

Regarding the action mechanism of the defoamer, it is generally believed that the low surface tension defoamer enters the part of the bi-molecular oriented bubble film, destroys the mechanical balance of the oriented bubble film, and causes foam breakage or foam suppression. There are many organic compounds suitable for defoaming agents, such as silicone oil, polyether, alcohol, fatty acid, phosphate and metal soap. From the structural point of view, non-silicon defoamers are organic compounds or polymers with polar groups at one or both ends of the molecule. They are similar to foaming agents, so improper use will have the effect of foaming agents. Its spreading coefficient is large, the foam breaking effect is very strong, but the foam suppression effect is poor.

According to physical properties,

silicone defoamers are mainly divided into four categories, namely silicone oil type, silicone oil solution type, silicone oil mixture type and silicone oil emulsion type. Silicone oil defoamers used in the paper industry can be of silicone oil type or silicone oil emulsion type. At present, silicone oil emulsion type is mainly used.

After the silicone oil is emulsified, the surface tension decreases rapidly, so it is easy to adsorb on the surface of the foam liquid and spread on the liquid surface. The formed surface film has low viscosity and low strength, so it can cause local surface tension imbalance on the foam and reduce the liquid film. It is thin and ruptured to achieve the purpose of defoaming, and at the same time, it also has the effect of suppressing foam. In addition, the emulsion type defoaming agent has a greater affinity for water, a wide range of pH values, and has no adverse effect on sizing. Stain on the surface of the paper. And using a small amount can achieve strong foam breaking and foam suppression, so it becomes an important defoamer component.

Silicone oil-type defoamers generally have high defoaming efficiency, and the key to their use is the emulsification of silicone oil. If the emulsification is not complete, the emulsion will be broken during use, which will affect its use effect. Commonly used organosilicon defoamers are made of silicone oil as the basic component, and suitable solvents, emulsifiers or inorganic fillers.

Top Win

Top Win is one of the leading & professional manufacturers with more than 20 years' experience, have domestic top-level engineers in silicone surfactant industry. We specialized in producing all kinds of SILICONE BASED new materials and specialized in research, production, sales and marketing in silicone-based performance materials.Provide good OEM&ODM service.Our products are mainly used in polyurethane foam, textile and leather, inks and coatings, paper release coating, personal care and agriculture, etc.