Polyesters are versatile polymers formed from a combination of dicarboxylic acids and diols. Their diverse applications depend on their production method and the resulting molecular arrangement.

Uses of Polyesters

Polyesters play a crucial role in various industries, notably in clothing, food packaging, and the production of plastic bottles for water and carbonated beverages.

The most commonly utilized polyester, known as polyethylene terephthalate (PET), is derived from benzene-1,4-dicarboxylic acid (terephthalic acid) and ethane-1,2-diol. With an annual worldwide production of approximately 40 million tonnes and a growth rate of about 7% per year, PET finds its way into 65% of fiber production, 5% in film production, and 30% in packaging.

Another notable polyester, polytrimethylene terephthalate, is derived from benzene-1,4-dicarboxylic acid and propane-1,3-diol, offering unique properties.

The structural composition of polyesters influences their applications. The presence of benzene rings in the molecular chain imparts rigidity, resulting in high melting points exceeding 500 K and exceptional strength. Moreover, polyesters exhibit resistance to discoloration when exposed to light.

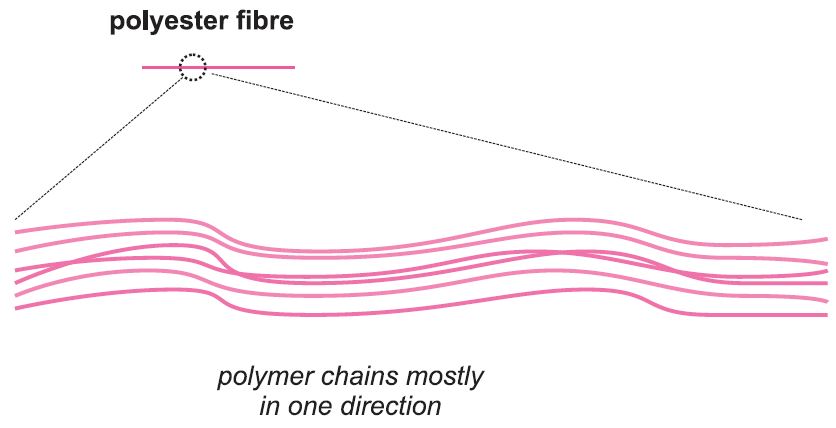

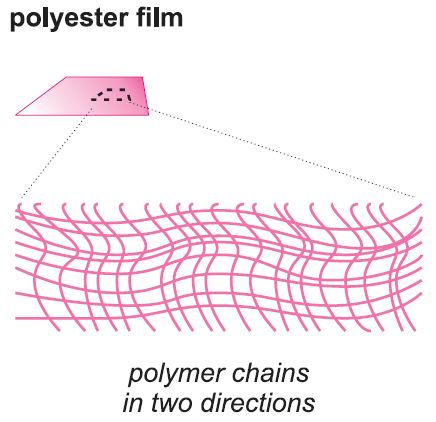

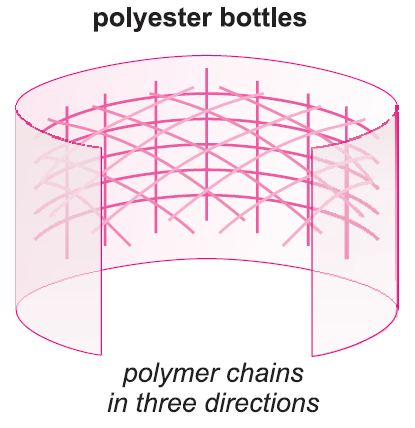

In PET fibers, molecules are predominantly aligned in one direction, while in films, they are oriented in two directions, and in packaging, they are arranged in three directions (see Figure 1).

Figure 1: [Diagram depicting the arrangement of PET molecules in fibers, films, and packaging]

Polyester Applications:

1. As Fibers: Polyester granules are melted and extruded through fine holes to produce filaments, commonly known as Terylene or Dacron. These fibers are extensively used in clothing, such as suits, shirts, and skirts, either alone or blended with other natural or synthetic fibers like cotton. Additionally, they find applications in filling for anoraks and bedding duvets due to their excellent heat insulation properties. Industries such as automotive utilize polyester fibers in car tire cords, conveyor belts, and hoses, benefiting from their strength and resistance to wear.

2. As Films: Polyesters can be processed into thin films suitable for various applications, including food packaging, audio and video tapes, electrical insulation, and X-ray films.

3. As Packaging: Polyester is increasingly employed in packaging, particularly for bottles (see Figure 3). Through a process involving heating to approximately 500 K and solid-state polymerization, the polyester granules are melted, molded, and stretched, resulting in a highly durable plastic with molecules oriented in three directions, ensuring superior strength.

Figure 3: [Image showcasing the use of PET in beverage packaging]

Manufacture of PET:

a) Production of the Monomer: The monomer for PET is derived from the reaction between ethane-1,2-diol and benzene-1,4-dicarboxylic acid or its dimethyl ester, employing a catalyst. Initially, low molecular mass oligomers are formed, which then undergo polymerization.

b) Polymerization of the Monomer: Polycondensation of the monomer, facilitated by a catalyst such as antimony(III) oxide, occurs at high temperatures (535-575 K) and low pressures, resulting in the formation of polyester. Continuous processes are favored for polyester fiber production, eliminating several intermediate stages present in batch processing.

Manufacture of Benzene-1,4-Dicarboxylic Acid: Benzene-1,4-dicarboxylic acid, a crucial component in PET production, is manufactured via the oxidation of 1,4-dimethylbenzene (para-xylene). Further purification steps ensure the quality required for PET production.

The utilization of bio-based 1,4-dimethylbenzene represents a recent development, allowing for the production of bio-based polyesters, thereby enhancing sustainability in polyester manufacturing.